The Future Of 3D Printing Is Bright, How Does It Need To Evolve?

3D printing involves so many fields that it is naturally endowed with the mission of “industrial revolution”, relatively primitive applications such as mold making, architectural printing, etc., while higher-end bioprinting, cell bonding, etc., 3D printing technology The ultimate goal in the biological field is to precisely control biological materials, biological factors, to combine in accordance with normal structures, to produce activity, and to be combined with natural human structures for organ replacement purposes.

3D printing, a revolutionary additive manufacturing

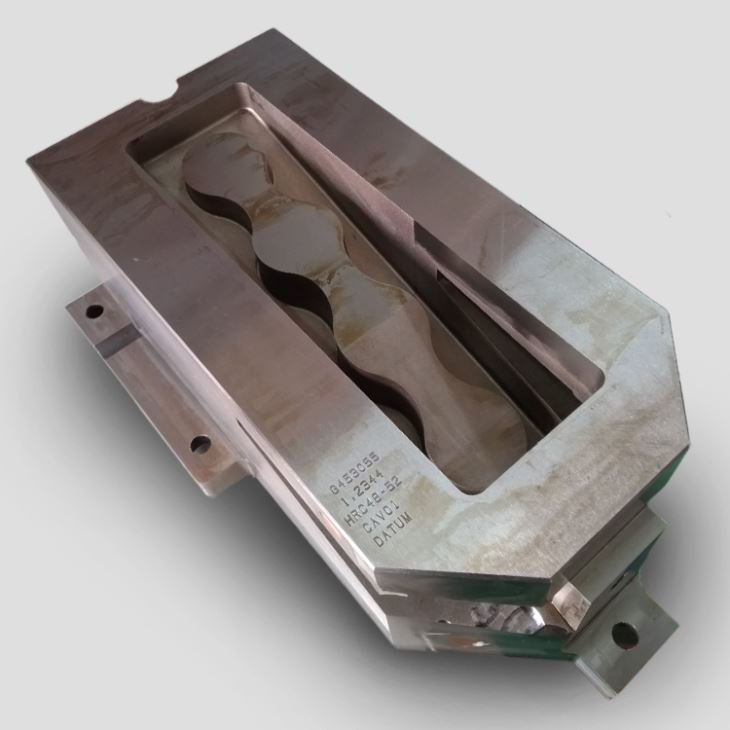

The traditional mold industry is a kind of “material reduction”. If the iPhone frame is removed, the precision is high. It is a work of art. This requires the company to configure ultra-high-precision tools and precision molding systems. In part, the size of the iPhone is even up to 0.01mm. In addition, the entire frame of the iPhone is its antenna. Any difference in the size of the burrs and screw holes will cause signal problems. The death of the iPhone 4 in the early years is due to its inaccurate design.

“Reducing material manufacturing” in this state is a very arduous thing. To “cut” a square piece of iron into a thin piece of iron, it needs to undergo molding, riveting, grinding, electroplating, etc. A lot of links, all the process down, the yield rate will be greatly affected, but if you change the idea of additive manufacturing, pre-set the precision program, 3D printed brush head no longer need to overcome the huge resistance like “precision tool”, Just add the material in the air according to the program, and there will be no extra burrs. The whole process will become very simple and the yield will be better.

Of course, according to the existing 3D printing technology, there is no way to complete the precision mold production such as the iPhone frame. However, there is no similar mature case in the precision program.More important is the development of basic raw materials, which requires the discovery of a material that can be ground into powder and ejected with the printer. Finally, it is also necessary to bond together in time according to the drawings. This complicated process is still under development, and at the same time, it is left to the traditional mold industry for some upgrades.

In all fairness, iPhone-style precision mold printing can be used as the ultimate goal of 3D printing additive manufacturing. It is estimated that there is still a long way to go before mass production, but the current delicate toys, household utensils such as cups, dishes, etc. , can already be completed by 3D printing. The larger product is a 3D printed house. Under the relatively mature system, a 300-square-meter villa is completed by a 3D printer. It takes only 24 hours, and the thickness of the wall can reach 30cm or more. The floor structure can be Superimposed to 2~3 layers. Relatively speaking, the application of 3D printing in the field of construction has already seen the dawn of “production”: special mortars and special concretes have a relatively mature formula, and the system of mechanical, control, running speed and nozzle discharge is also in dire perfect.